Green Tick for Ohaus Scout (TM) SKX portable precision balance series

Ohaus is a multinational corporation that serves distributors across the world and has its headquarters in New Jersey, USA. It has a long history of producing quality balances for education and industry and is a brand associated with quality and precision.

The ScoutTM SKX portable precision balance series is specifically designed for school use, with several features that make it ideal for use in the school laboratory. In total, there are eleven balances in the series, covering a capacity from 120 g to 8200 g, with a readability of 0.1 g to 0.001 g. They can be used with batteries (four AA), or with a supplied mains power unit. Each has a socket for connecting an RS232 interface cable and each has Bluetooth® wireless connectivity. However, testing the connectivity features was beyond the scope of this evaluation.

Three balances from the series were evaluated:

- SKX123: Capacity 120 g x 0.001 g

- SKX622: Capacity 620 g x 0.01 g

- SKX6201: Capacity 6200 g x 0.1 g

Tests

A series of tests was conducted using the balances. These tests included:

- Setting up

- Visual tests

- Functionality:

- Mass measurements using precision masses

- Density measurements using two methods

- Mole measurements

- Counting

- Customisation

- Power options

Test results

Setting up

Each balance is suppled well-packed within polyethylene foam in a cardboard box. One box had been damaged in transit, but the foam had fully protected the balance . The pan support platen has a transport lock to prevent damage caused by heavy handling. It takes a mere sixty seconds to remove the packaging and set the balance up ready for use.

Visual tests

All balances are made from impact-resistant ABS in white and red.Each has the same control panel, connections for power input and RS232 interface, and a non-magnetic stainless-steel pan. Each balance is relatively light in weight at between 800g and 1000g, but each feels relatively solid.

SKX123 (capacity 120 g x 0.001 g) looks rather different, as it has a hinged draught shield. SKX622 (capacity 620 g x 0.01 g) and SKX6201 (capacity 6200 g x 0.1 g) are each supplied with a clear plastic cover that sits over the entire balance. The cover is designed such that balances can be stacked, making storage in the prep room efficient and transporting them on equipment trolleys secure.

Each balance has a ‘security slot’ for attaching an anti-theft cable (available as an accessory), and each has a security switch on the underside: switching to the ‘locked’ position prevents the balance from entering the ‘calibration’ mode.

The battery compartment cover does not have a security screw, which may make schools hesitant about using them with batteries, however a solid mains power unit is supplied.

Functionality

There are three main functions available by toggling though a menu. The default setting is ‘weight’ (sic) with two other settings available – ‘specific density’ and ‘mole’.

- Mass measurements

- The main purpose of a balance is for determining mass and all three balances performed well. Absolute accuracy of mass measurement was not determined, as suitable calibration masses were not available However, precision masses showed that each balance stabilised quickly, and provided an accurate reading consistent across the range for each balance, and consistent between balances. Should schools need to check absolute precision, each balance can be span calibrated and linear span calibrated using suitable masses. When contacted, Ohaus confirmed that models bought in the UK will now be supplied with both a fixed moulded EU and UK type plug, and include the calibration masses.

- The main purpose of a balance is for determining mass and all three balances performed well. Absolute accuracy of mass measurement was not determined, as suitable calibration masses were not available However, precision masses showed that each balance stabilised quickly, and provided an accurate reading consistent across the range for each balance, and consistent between balances. Should schools need to check absolute precision, each balance can be span calibrated and linear span calibrated using suitable masses. When contacted, Ohaus confirmed that models bought in the UK will now be supplied with both a fixed moulded EU and UK type plug, and include the calibration masses.

- Specific density measurements using two methods

- Each balance is provided with a threaded hook stored in the battery compartment. The hook can be screwed into the underside of the platen after a cover has been removed from the underside of the balance. The balance can then be supported on a platform, and objects suspended from the hook.

- Each balance is provided with a threaded hook stored in the battery compartment. The hook can be screwed into the underside of the platen after a cover has been removed from the underside of the balance. The balance can then be supported on a platform, and objects suspended from the hook.

After the ‘specific density’ mode has been selected, a ‘dry’ mass for the object is determined and confirmed on the balance. A beaker of water is then brought up to the object such that it becomes fully immersed, and a ‘wet’ mass is determined and confirmed. The balance then returns a value for the specific gravity as a ratio of water to object density. If conducted at room temperature with pure water, the specific density is very close numerically to the density of the object in g/cm3 (rather than the SI unit of kg/m3.)

The method worked well for determining the density of two small irregular-shaped objects – a 12mm metric thread nut and a 1g precision mass. One minor drawback is that the specific gravity answer is quoted to four significant figures rather than two or three, and so students may need guidance in interpreting and recording data appropriately.

- The second method for specific gravity determination uses a top loading kit – a hook that attaches to the platen and a stand that replaces the top pan for supporting a beaker of water. This is available as an accessory and was not available for testing. However, a freestanding hook made from a wire coat-hanger that sat on the top pan worked well, although a steady hand to hold a beaker of water for the second measurement was needed!

- Memory

- The balance ‘remembers’ the mode for which it was last used, even without batteries and when the low voltage supply has been disconnected. This is a useful feature, as balances can be set up in the prep room prior to sending them to a lab. However, teaching staff will need to be aware that balances may not have the correct mode set when they are delivered to the lab, especially if they did not request them to be set up. Teaching staff may well need a crash course in how to set up a balance, and how to change between modes before using them with students.

- Mole measurements

- Once the ‘mole’ mode has been selected, the molar mass for a compound can be entered into the balance to two decimal places. Placing a sample of the balance will provide a readout of the number of moles, rounded to the nearest mole, which prevents it being used to determine fractional numbers of moles. Given that specific gravity values are returned to four significant figures, this is both surprising and disappointing. However, a simple workaround would be to enter the molar mass as one tenth of the actual value, which would return a value for the number of moles ten times greater than the actual value. This feature may be particularly useful for time-pressed technicians when setting up large numbers of samples.

Setting up the balance to measure moles is not initially a quick process but, after working with it a few times, it becomes far easier and would save a lot of time for repeated weighings.

After contacting Ohaus, ASE has been informed that it is possible that Ohaus could make software modifications, but there would need to be significant market feedback for this to be implemented.

- Once the ‘mole’ mode has been selected, the molar mass for a compound can be entered into the balance to two decimal places. Placing a sample of the balance will provide a readout of the number of moles, rounded to the nearest mole, which prevents it being used to determine fractional numbers of moles. Given that specific gravity values are returned to four significant figures, this is both surprising and disappointing. However, a simple workaround would be to enter the molar mass as one tenth of the actual value, which would return a value for the number of moles ten times greater than the actual value. This feature may be particularly useful for time-pressed technicians when setting up large numbers of samples.

- Counting

- This is a feature not identified in the manual, but is one that uses the ‘mole’ function. To count out items such as paper clips, the mass of one paperclip is entered as the molar mass. Clearly, the balance will show the number of paperclips on the balance when in the ‘mole’ mode. Once again, time-pressed technicians may find this a very helpful feature.

- Customisation

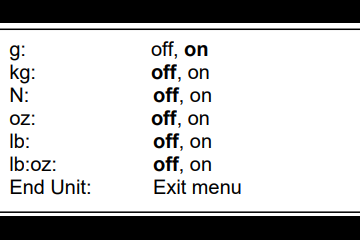

- There is a ‘set-up’ mode that allows certain options to be selected or deselected. For example, the factory default setting only has the gram as the active measuring unit, although other units may be enabled: kilograms, newtons, ounces, pounds, and pounds and ounces. If enabled, they may then be accessed and selected.

- Similarly, it is possible to disable the ‘specific density’ mode and the ‘mole’ mode to prevent students inadvertently switching to the wrong mode.

- Other setting adjustments that affect the balance sensitivity and power-saving (if used with batteries) are also possible.

- A most useful option is to reset the balance to factory defaults, should settings have been altered inadvertently or maliciously. This option allows a balance to be quickly recommissioned. It should be noted that the reset function within the menu only resets the setup, mode and unit settings back to factory default. For example, it would reset the unit menu so that only measurements in grams are available as that is the factory default (in bold):

- It should be noted that certain settings, such as mole settings, are retained even after a reset.

Conclusions

The Ohaus ScoutTM SKX portable precision balance series is well designed and manufactured. The software operating the balance is sophisticated and well thought-out, with the exception of the mole function reporting to the nearest whole number of moles. As might be expected from Ohaus, there is comprehensive support through supply of accessories, manuals, drivers and video tutorials. This includes possible software updates. It is possible for end users to update the software in their SKX balances using the Ohaus repair and service tool and a RS232 or USB interface. However, Ohaus strongly recommend that updates are only carried out by servicing dealers. Considering the functionality of the balances and the entire support package, they represent good value for money.

SKX123 from about £300 (ex VAT)

SKX622 from about £260 (ex VAT)

SKX6201 from about £260 (ex VAT